If you need help, please feel free to contact us.

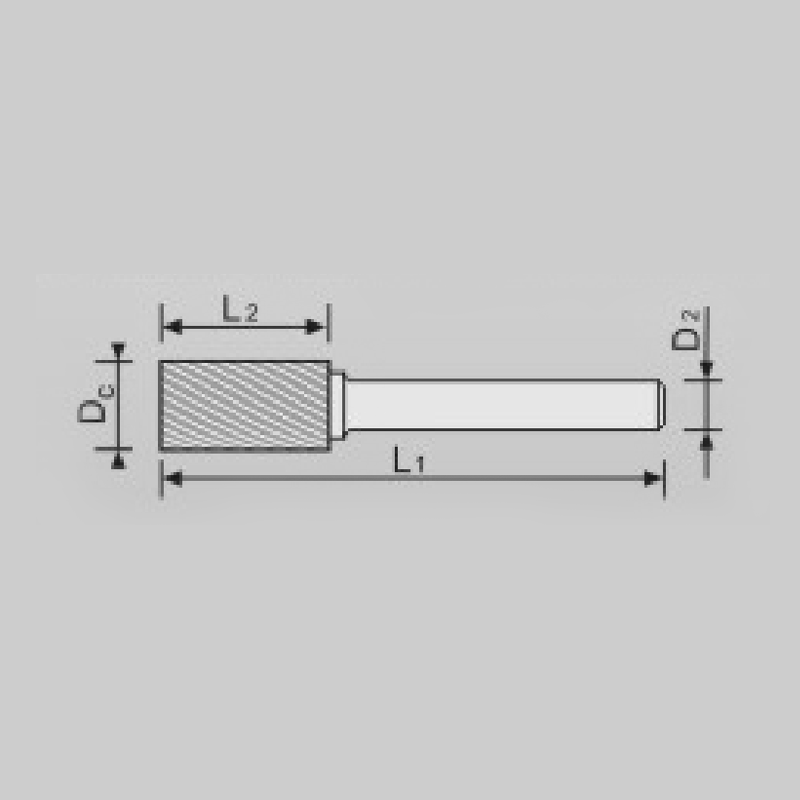

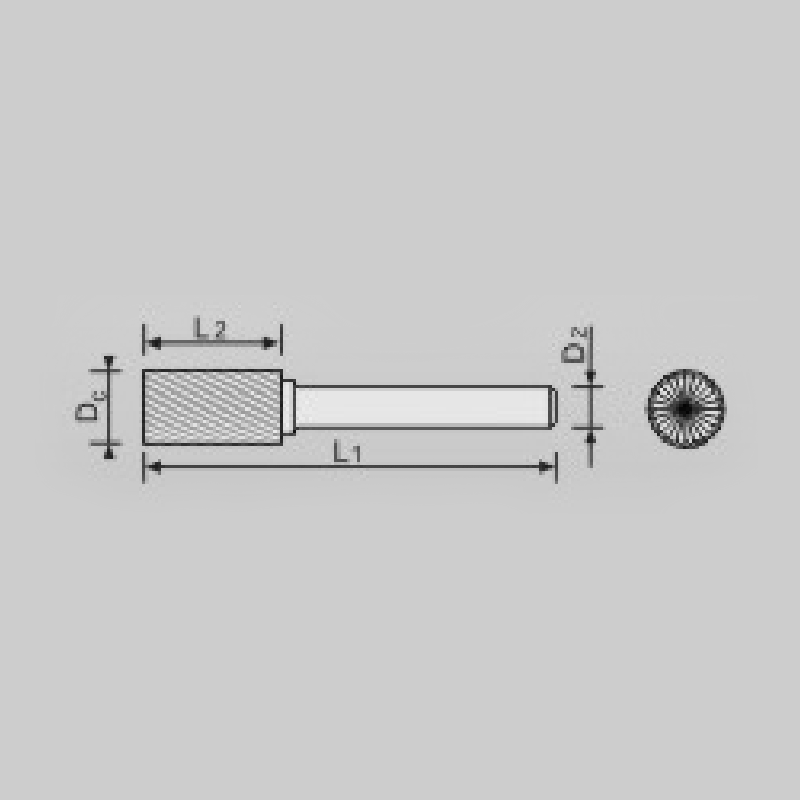

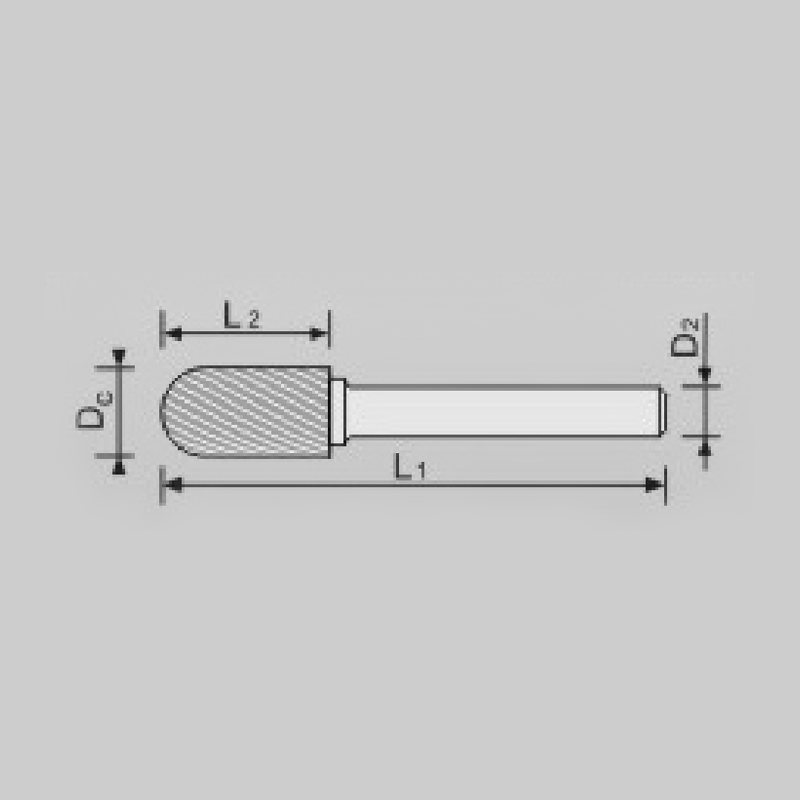

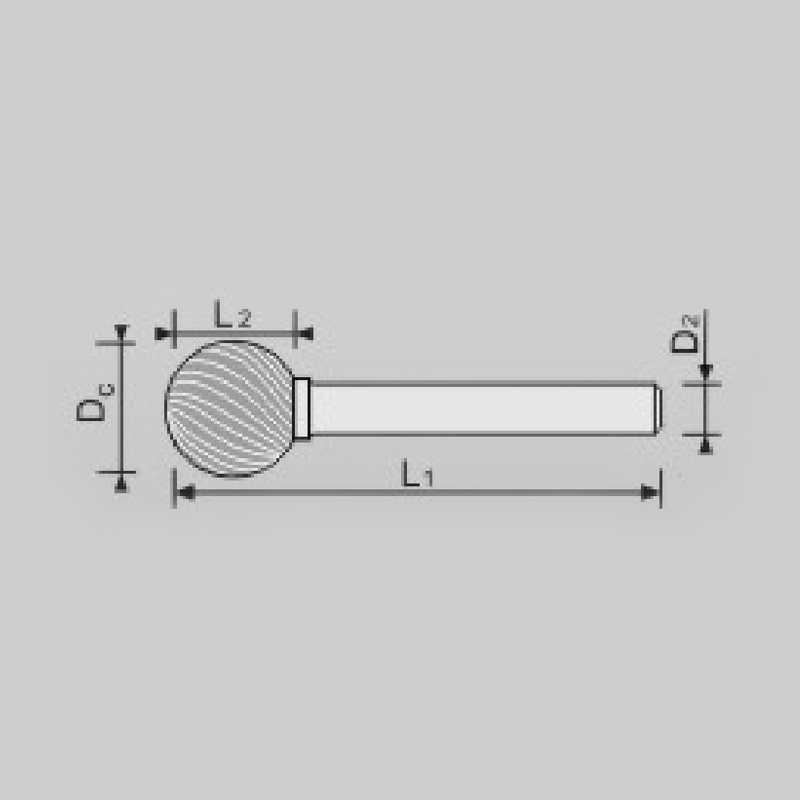

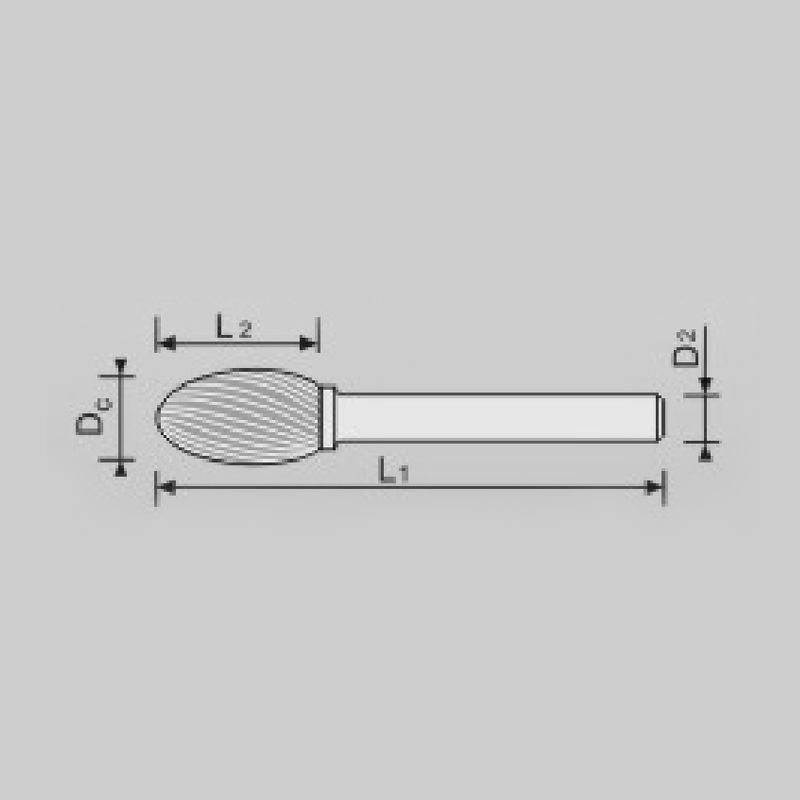

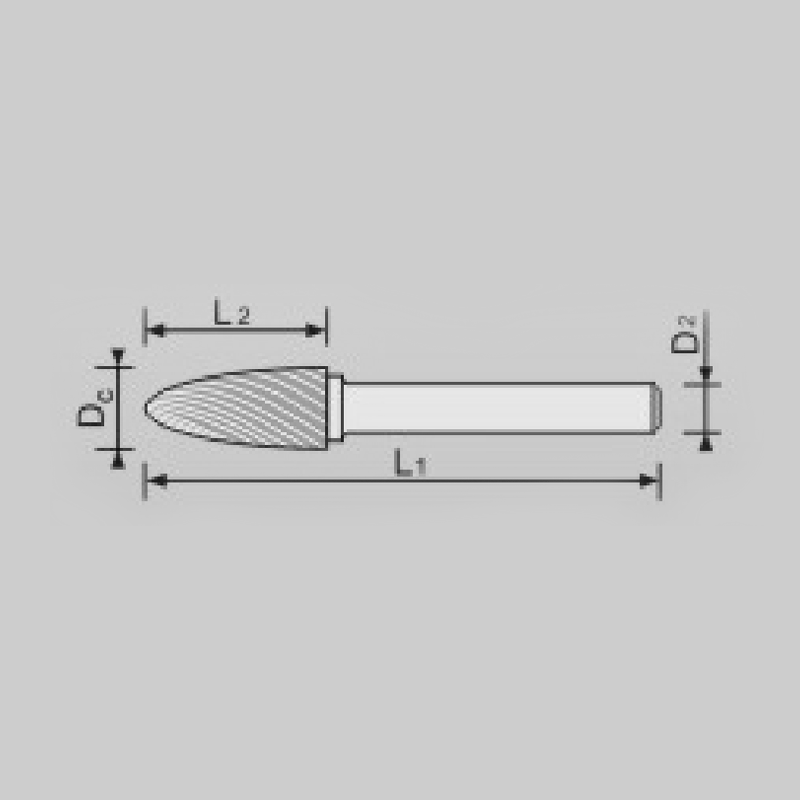

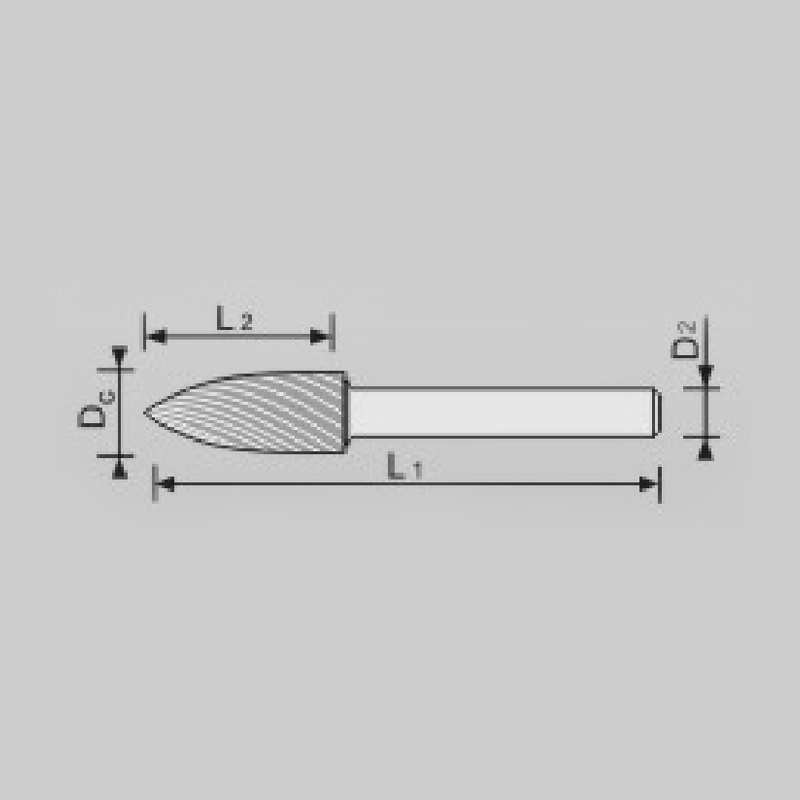

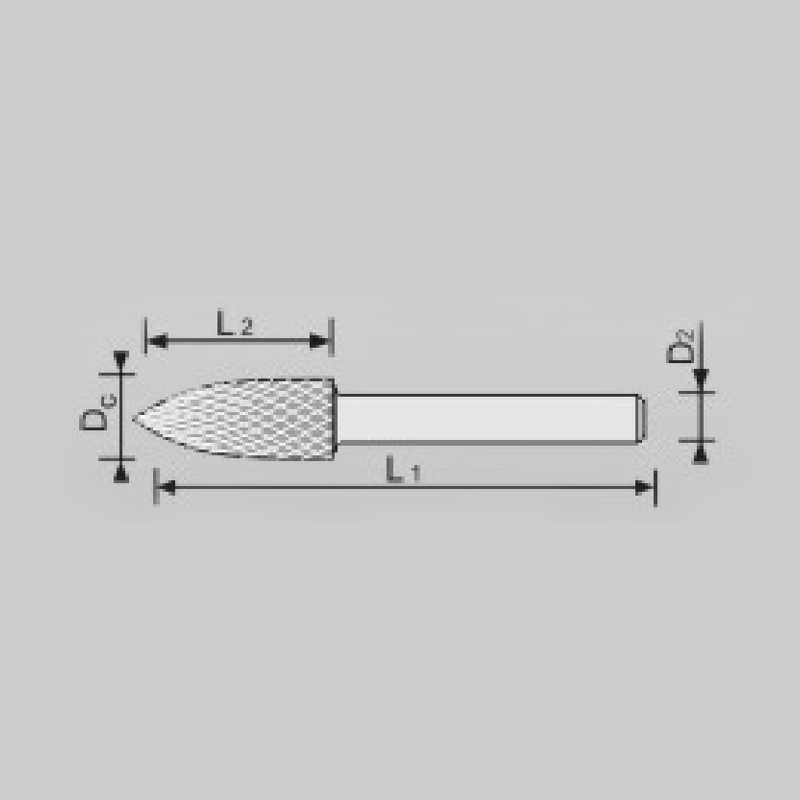

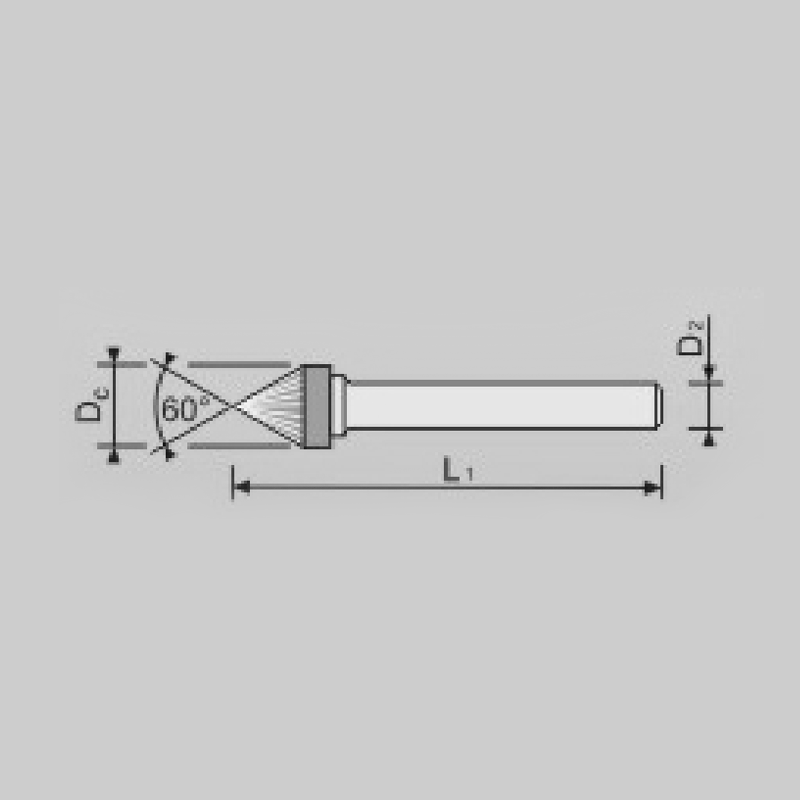

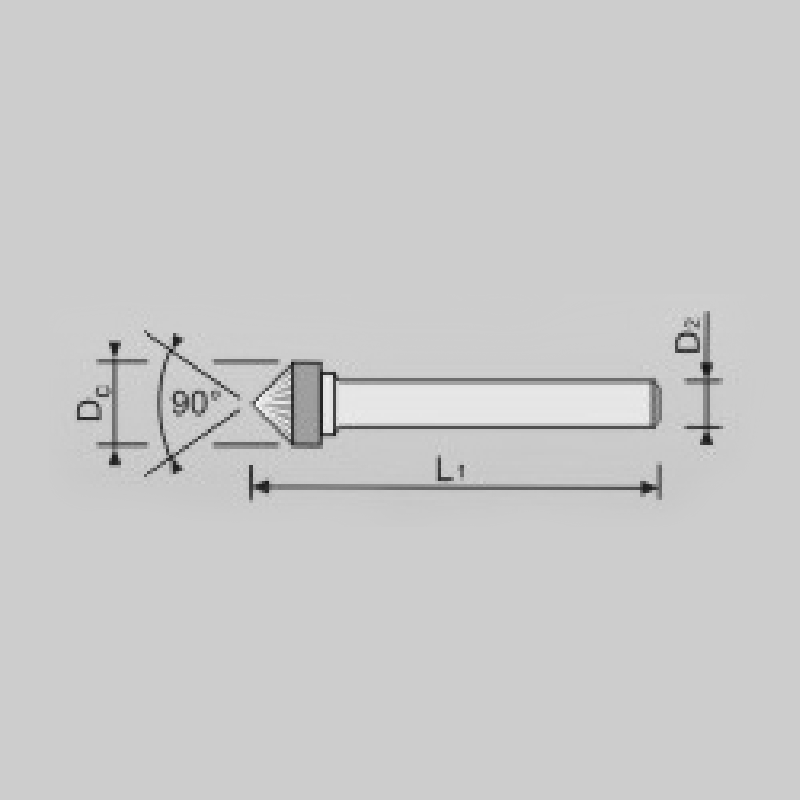

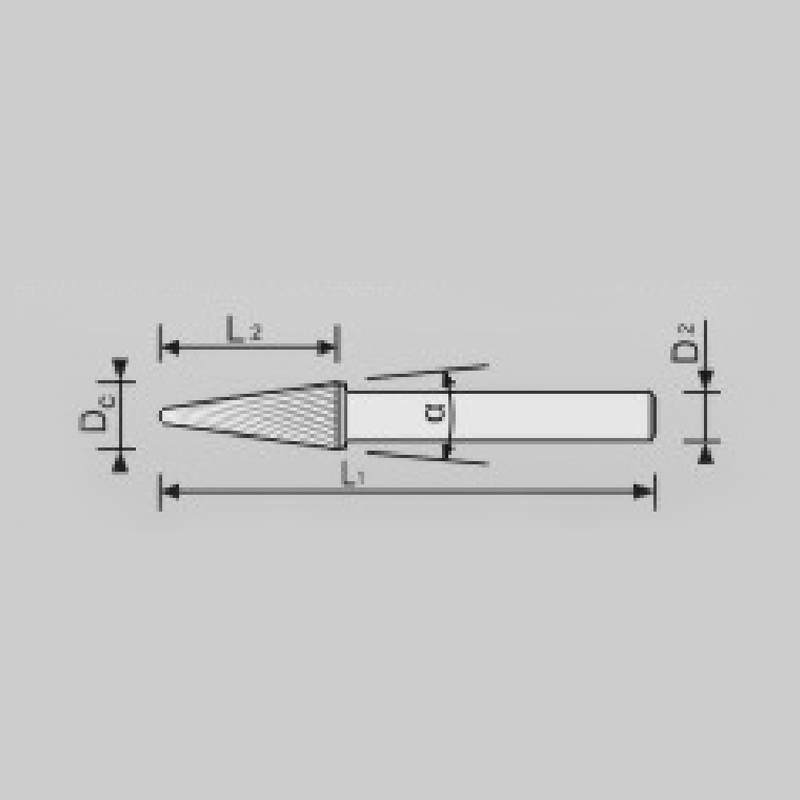

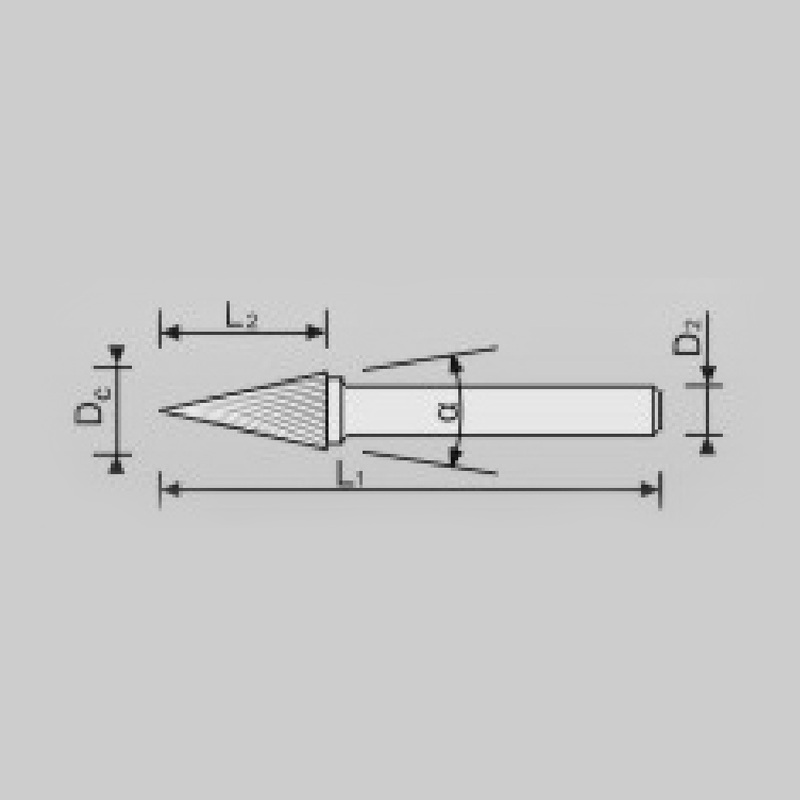

Custom Rotary Cutting Tool

In the realm of precision machining, the selection of tools plays a pivotal role in determining the quality, efficiency, and accuracy of the end product. Standard Rotary Burs stand as stalwart companions in this journey towards excellence, offering a plethora of capabilities and advantages that cater to the diverse needs of industries ranging from automotive to aerospace, from healthcare to woodworking.

Applications:

Standard Rotary Burs are versatile tools with applications spanning various industries and tasks. In automotive, they're indispensable for tasks like porting cylinder heads, polishing engine components, and shaping metal parts precisely. Aerospace relies on them for intricate machining tasks on aircraft components, from shaping turbine blades to creating precision holes in structural elements. Healthcare benefits from their precision in fabricating dental implants, orthopedic devices, and surgical instruments, ensuring meticulous precision and surface finish. Additionally, woodworking craftsmen utilize these burs to shape, carve, and detail wooden pieces with finesse.

Characteristics and Features:

1. Precision Cutting: Equipped with sharp cutting edges and fine tooth configurations, Standard Rotary Burs excel in precise material removal, delivering smooth surface finishes with minimal effort.

2. Versatility: Compatible with various rotary tools such as die grinders, electric drills, and CNC machines, these burs offer adaptability and flexibility in machining setups, allowing for seamless integration into existing workflows.

3. Durability: Crafted from high-quality materials, Standard Rotary Burs exhibit exceptional durability, capable of withstanding prolonged use and high-intensity machining operations, ensuring longevity and reliability in performance.

4. Multi-tool Compatibility: Designed to accommodate different tool types and configurations, these burs can be easily interchanged and utilized across a range of machining applications, offering convenience and efficiency in tool selection.

Advantages:

1.Enhanced Precision:

The hallmark of Standard Rotary Burs lies in their ability to facilitate precise machining operations, elevating the standards of accuracy and consistency in part dimensions and surface finish. These burs act as precision instruments, finely honed to meet the exacting demands of modern manufacturing processes.

At the heart of their precision capabilities are meticulously crafted cutting edges and tooth configurations, engineered to deliver unparalleled accuracy with every pass. Whether it's shaping intricate contours or creating precise holes, these burs excel in maintaining tight tolerances and geometric fidelity.

2.Cost-effectiveness:

By streamlining machining processes and reducing the need for secondary operations, these burs contribute to cost savings and improved overall efficiency in manufacturing operations.Furthermore, the cost-effectiveness of Standard Rotary Burs extends beyond their precision capabilities. By streamlining machining processes and minimizing the requirement for secondary operations, these burs drive significant cost savings and enhance overall manufacturing efficiency. With reduced reliance on additional finishing processes, manufacturers can optimize resource utilization, minimize labor costs, and decrease turnaround times. Additionally, the longevity and durability of Standard Rotary Burs ensure prolonged usage, further amplifying their cost-effectiveness by lowering tool replacement and maintenance expenses. Ultimately, these burs emerge as indispensable assets in achieving leaner, more cost-efficient manufacturing operations.

3.Improved Surface Finish:

With their ability to achieve smooth surface finishes, Standard Rotary Burs enhance the aesthetic appeal and functional performance of machined components, meeting the stringent quality standards of various industries.

4.Versatile Application:

Standard Rotary Burs find application across a wide range of materials, including metals, plastics, and composites, making them suitable for diverse machining tasks and industries, from automotive and aerospace to medical device manufacturing and woodworking.

In conclusion, Standard Rotary Burs represent a cornerstone in the realm of precision machining, offering unparalleled capabilities, versatility, and advantages that cater to the diverse needs of modern industries. With their precision cutting, durability, and efficiency, these burs serve as indispensable tools for achieving machining results and driving innovation in manufacturing processes.