If you need help, please feel free to contact us.

Internal Grinding Tools Factory

Special Rotary Burs, nestled within the broader category of Standard Rotary Burs (Metric), represent a specialized class of precision machining tools engineered to meet the unique demands of specific applications and industries. From intricate dental procedures to intricate aerospace components, these burs offer bespoke solutions that marry precision with efficiency.

Applications:

Special Rotary Burs cater to a diverse array of specialized applications across industrial sectors, showcasing their versatility and indispensability in precision machining. In manufacturing, these burs are pivotal for tasks such as shaping intricate components, deburring machine parts, and refining surface finishes to exacting standards. Industries ranging from aerospace and automotive to electronics and mold making rely on Special Rotary Burs to achieve precision machining outcomes essential for product performance and quality assurance. Whether it's crafting precision components for aerospace engines, fine-tuning molds for plastic injection molding, or detailing intricate electronic parts, these burs excel in meeting the rigorous demands of high-stakes industrial environments. Their precision cutting capabilities, coupled with advanced materials and coatings, ensure performance and reliability in the face of complex machining challenges. In essence, Special Rotary Burs stand as indispensable tools for achieving machining results across a multitude of industrial applications, driving innovation and excellence in manufacturing processes.

Characteristics and Features:

1.Specialized Designs:

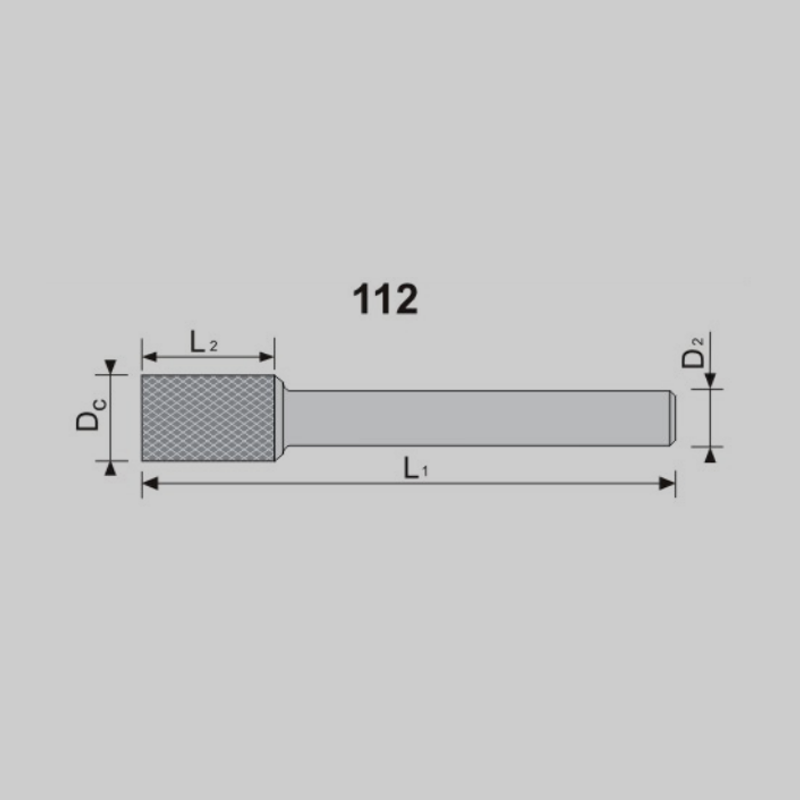

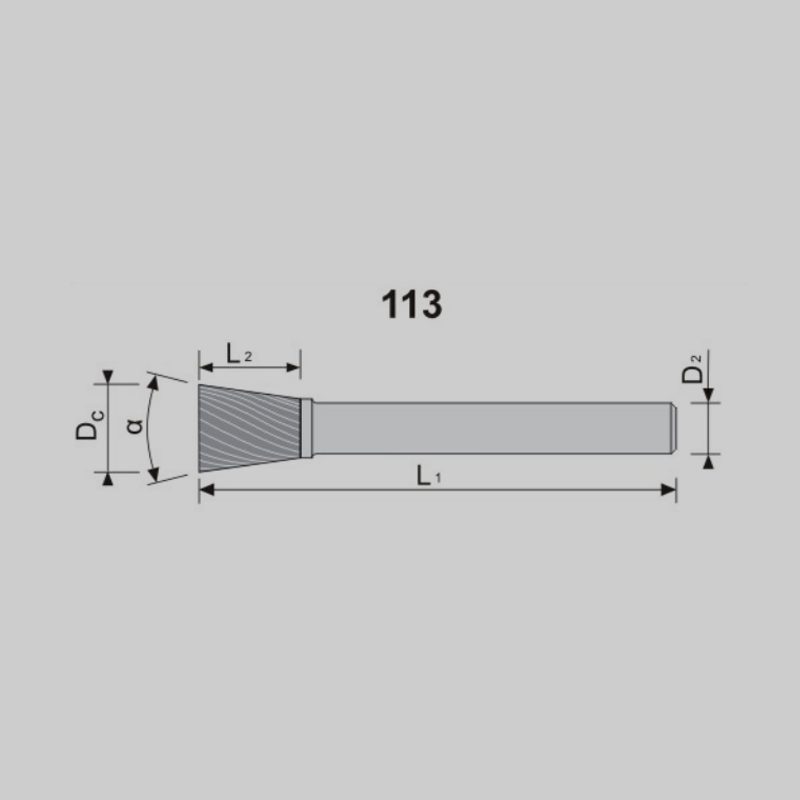

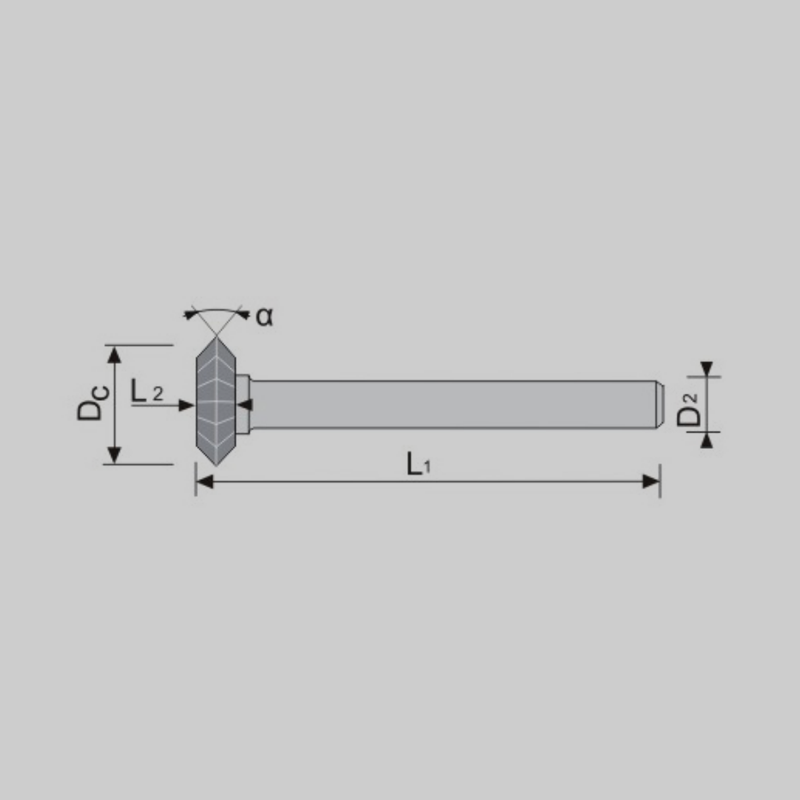

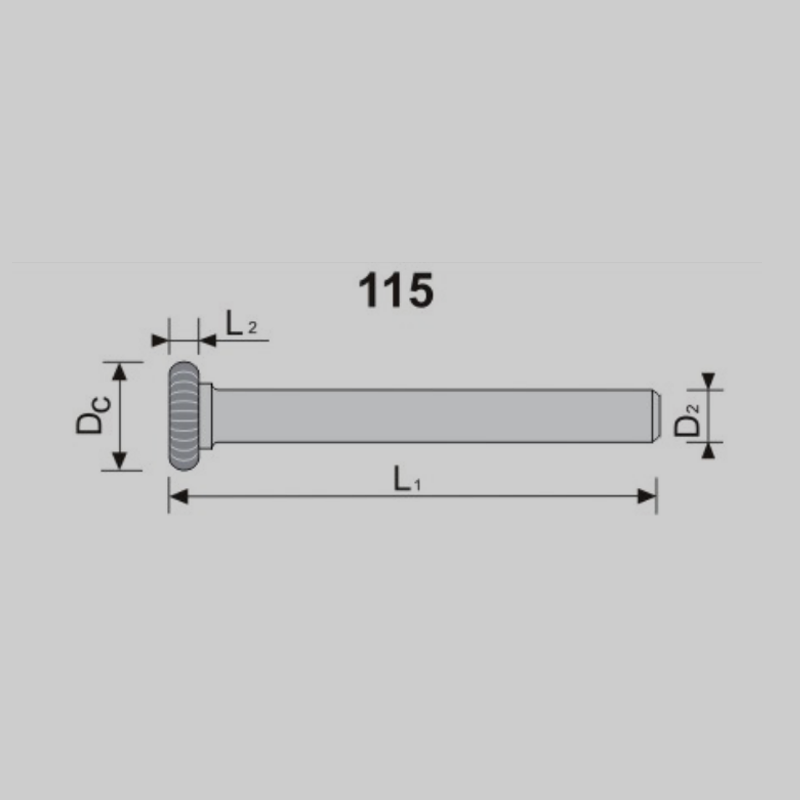

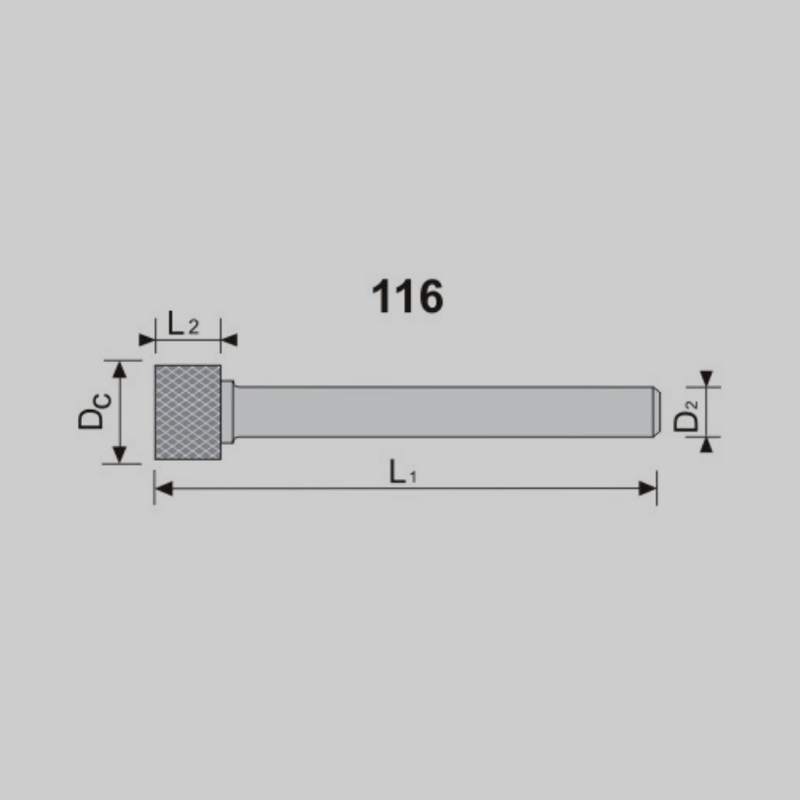

Special Rotary Burs offer a diverse array of specialized designs meticulously tailored to meet the unique machining requirements of various applications. Among these designs are specialized tools such as internal grinding tools, groover cutters at Y90°-100°-110° angles, and disc cutters, available in straight or radius configurations. Each design is engineered with precision and care to address specific machining challenges encountered in industries ranging from manufacturing and aerospace to electronics and mold making.

4.Precision Cutting: With razor-sharp cutting edges and fine tooth configurations, these burs excel in achieving precise material removal, resulting in surface finishes and dimensional accuracy.Special Rotary Burs elevate precision cutting to new heights, boasting razor-sharp cutting edges and intricately designed tooth configurations. This unparalleled precision enables meticulous material removal, ensuring not only surface finishes but also unmatched dimensional accuracy in machining operations.

5.Versatility: Despite their specialized designs, Special Rotary Burs are compatible with a variety of rotary tools, including dental handpieces, die grinders, and CNC machines, offering versatility and flexibility in machining setups.

Advantages:

1.Enhanced Precision: Special Rotary Burs enable precise machining operations, ensuring accuracy and consistency in part dimensions and surface finish, thereby reducing the need for additional finishing processes and improving overall productivity.

2.Optimized Performance: Tailored to specific applications, these burs deliver optimized performance, achieving results in terms of dimensional accuracy, surface finish, and machining efficiency.

3.Extended Tool Life: With their high-performance materials and advanced coatings, Special Rotary Burs offer extended tool life, reducing tool replacement costs and downtime, and increasing operational efficiency.

4.Versatile Application: Despite their specialized designs, these burs find application across a wide range of industries and tasks, offering versatility and adaptability to diverse machining requirements.

In conclusion, Special Rotary Burs stand as exemplars of precision machining excellence, offering tailored solutions for specific applications and industries. With their specialized designs, high-performance materials, and advanced coatings, these burs deliver unmatched precision, reliability, and efficiency, making them indispensable tools for achieving machining results across diverse industries and applications.