If you need help, please feel free to contact us.

Wholesale Long Shank Carbide Burr

Long Shank Burs, an integral subdivision within the Metric Standard Rotary Burs, epitomize a distinctive breed of precision machining instruments engineered to deliver extended reach and adaptability across a spectrum of industrial contexts. These burs stand as exemplars of specialized prowess, meticulously honed to address the intricate requirements of applications demanding profound penetration or maneuverability within constrained environments.

Characteristics and Features:

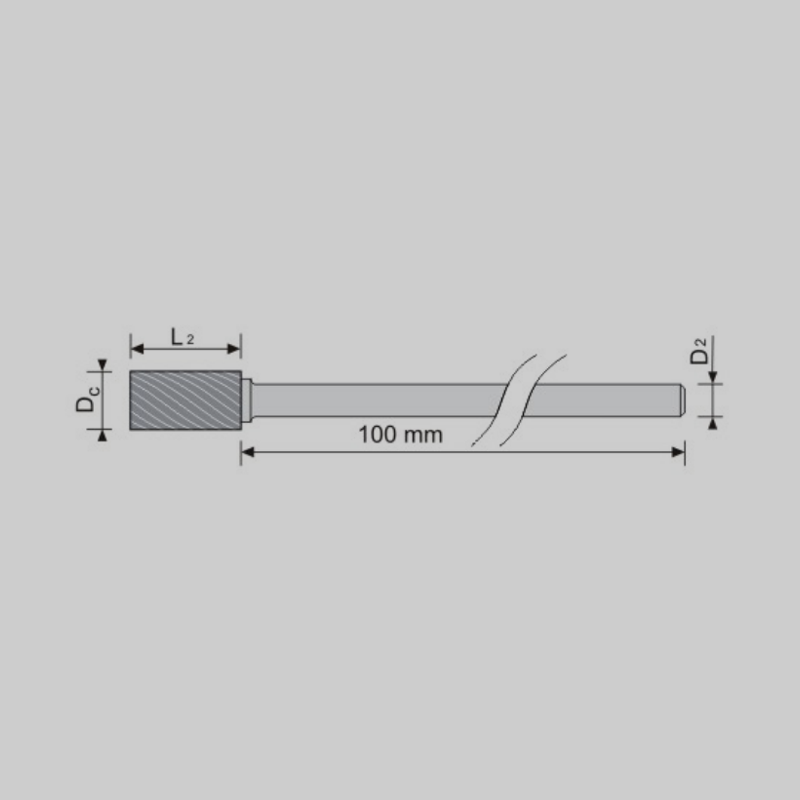

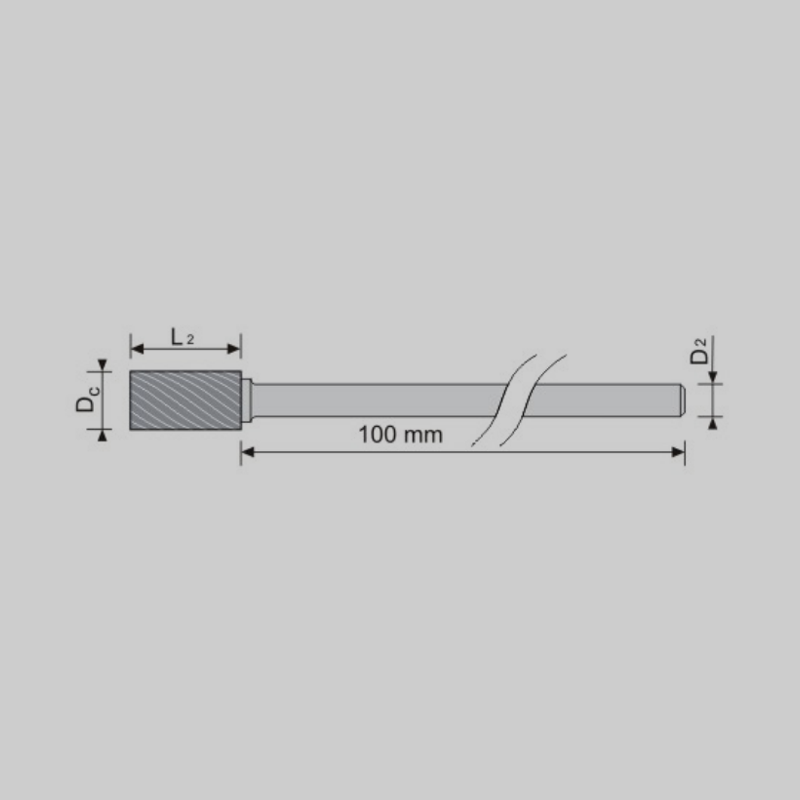

1.Two Variants: Long Shank Burs are available in two variants: Rotary burs with a shank length of 100mm and Rotary burs with a shank length of 150mm. Each variant is designed to address specific machining needs, offering flexibility and precision in different applications.

2.Precision Cutting: Equipped with razor-sharp cutting edges and fine tooth configurations, these burs excel in achieving precise material removal, ensuring surface finishes and dimensional accuracy.

3.High-Quality Construction: Crafted from premium-grade materials, Long Shank Burs exhibit exceptional durability and longevity, capable of withstanding prolonged use in high-intensity machining operations.

Advantages:

1.Extended Reach: The elongated shanks of Long Shank Burs serve as dynamic extensions, granting unparalleled reach into recesses and confined spaces previously beyond the scope of standard tools. This extended reach empowers precision machining in otherwise inaccessible areas, facilitating intricate operations with accuracy and finesse. By bridging the gap between conventional limitations and evolving machining demands, Long Shank Burs redefine the boundaries of what's achievable, unlocking new dimensions of precision and versatility in industrial applications.

2.Precision Cutting: With their razor-sharp cutting edges and fine tooth configurations, these burs ensure precise material removal, resulting in surface finishes and dimensional accuracy, reducing the need for additional finishing processes.

3.Tailored Solutions: With two variants available, Rotary burs with shank lengths of 100mm and 150mm, users can select the suitable option based on the depth of machining required, offering tailored solutions to meet specific application needs.

Difference between Rotary burs shank length 100mm and Rotary burs shank length 150mm:

The primary difference between the two variants lies in the length of the shank. Rotary burs with a shank length of 100mm are designed for applications requiring moderate reach, providing sufficient length for accessing recessed areas or machining intricate components. On the other hand, Rotary burs with a shank length of 150mm offer extended reach, making them suitable for tasks requiring deeper access or machining in confined spaces. The choice between the two variants depends on the specific requirements of the application, with each variant offering unique benefits and capabilities tailored to different machining scenarios.

Applications:

Long Shank Burs find diverse applications across multiple industries, owing to their extended reach and precision cutting abilities. In the aerospace sector, they are indispensable for machining intricate components within aircraft engines or fuselages, where access is restricted. Additionally, in the automotive industry, Long Shank Burs play a crucial role in tasks such as porting and polishing engine cylinders or deburring complex components. Furthermore, they are utilized in industries like metalworking, mold making, and jewelry manufacturing, where precise machining in deep recesses or intricate details is essential.

In conclusion, Long Shank Burs stand as indispensable tools in precision machining, offering extended reach and exceptional cutting performance for a wide range of industrial applications. With their versatility, precision, and tailored solutions, these burs empower manufacturers to achieve machining results, driving efficiency and innovation in manufacturing processes.