If you need help, please feel free to contact us.

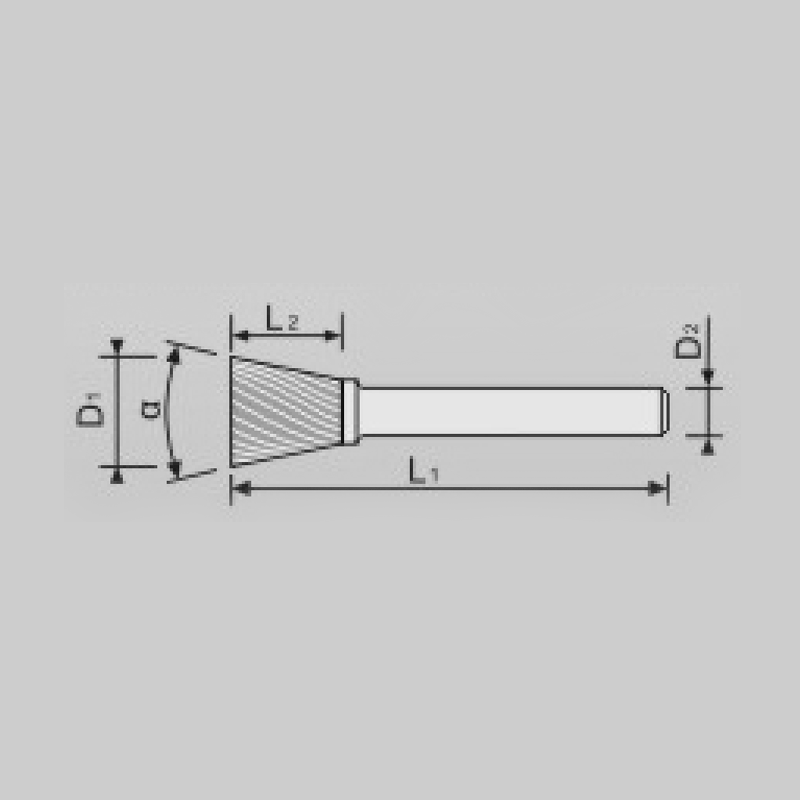

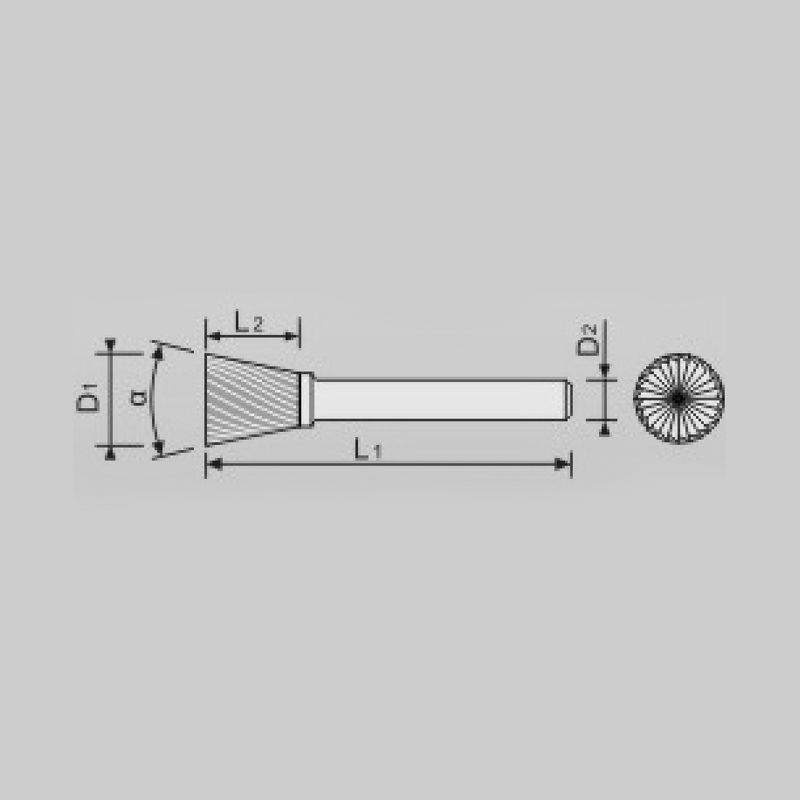

Wholesale Cylindrical Rotary File

In the realm of precision machining, Standard Rotary Burs stand as indispensable tools, offering unparalleled capabilities and advantages that cater to the diverse needs of industries ranging from automotive to aerospace, from healthcare to woodworking. This classification, Standard Rotary Burs (Fractional), embodies precision and efficiency, serving as a cornerstone for achieving machining results and driving innovation in manufacturing processes.

Applications:

Standard Rotary Burs (Fractional) find extensive application across a myriad of industries and tasks. In the automotive sector, they play a crucial role in tasks such as porting and polishing cylinder heads, deburring engine components, and shaping metal parts with precision. Within the aerospace industry, these burs are utilized for intricate machining operations on aircraft components, such as shaping turbine blades or creating precision holes in structural elements. In the healthcare field, Standard Rotary Burs (Fractional) aid in the fabrication of dental implants, orthopedic devices, and surgical instruments, ensuring meticulous precision and surface finish. Furthermore, they are instrumental in woodworking, enabling craftsmen to shape, carve, and detail wooden pieces with finesse.

Characteristics and Features:

1.Precision Cutting: Equipped with sharp cutting edges and fine tooth configurations, Standard Rotary Burs (Fractional) excel in precise material removal, delivering smooth surface finishes with minimal effort.

2.Durability: Fashioned from premium-grade materials, Standard Rotary Burs epitomize durability, showcasing remarkable resilience against prolonged usage and high-intensity machining endeavors. Their robust construction ensures prolonged endurance, guaranteeing consistent performance and reliability over extended periods of operation. Crafted with meticulous attention to detail, these burs withstand the rigors of demanding machining tasks, delivering longevity that surpasses industry standards. With unwavering durability as their hallmark, Standard Rotary Burs stand as steadfast allies in achieving enduring excellence in machining operations.

3. Wide Range of Shapes and Sizes: Available in various shapes and sizes, including cylindrical, ball, and flame shapes, Standard Rotary Burs cater to diverse machining needs, allowing for precise customization and optimization of machining processes.

4. Efficiency: With their efficient cutting capabilities and high-speed performance, these burs enable rapid material removal and machining operations, contributing to enhanced productivity and reduced machining times.

Advantages:

1.Enhanced Precision: Standard Rotary Burs (Fractional) facilitate precise machining operations, ensuring accuracy and consistency in part dimensions and surface finish, thereby minimizing the need for additional finishing processes.

2.Improved Surface Finish: With their ability to achieve smooth surface finishes, Standard Rotary Burs (Fractional) enhance the aesthetic appeal and functional performance of machined components, meeting the stringent quality standards of various industries.Moreover, the improved surface finish achieved by Standard Rotary Burs (Fractional) not only enhances the aesthetic appeal of machined components but also elevates their functional performance. This surface quality ensures that parts meet the exacting standards demanded by diverse industries, instilling confidence in the reliability and integrity of the final products.

3.Versatile Application: Standard Rotary Burs (Fractional) find application across a wide range of materials, including metals, plastics, and composites, making them suitable for diverse machining tasks and industries, from automotive and aerospace to medical device manufacturing and woodworking.

In summary, Standard Rotary Burs (Fractional) epitomize precision cutting solutions at their zenith, presenting unparalleled capabilities, adaptability, and benefits that propel efficacy and ingenuity in contemporary manufacturing methodologies. Armed with precision cutting, resilience, and effectiveness, these burs emerge as indispensable instruments for attaining machining outcomes spanning diverse industries and applications.