If you need help, please feel free to contact us.

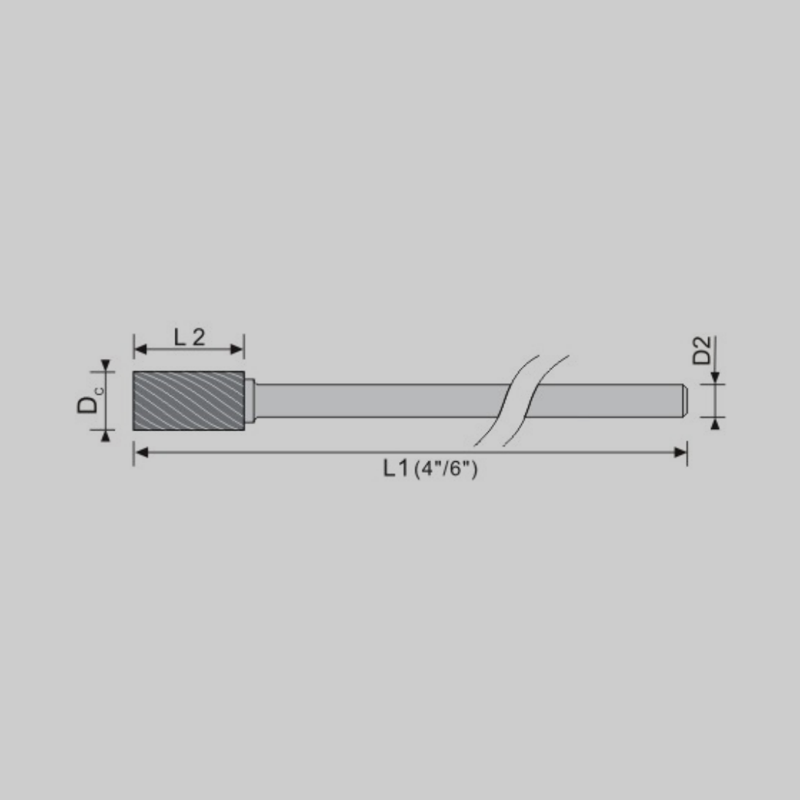

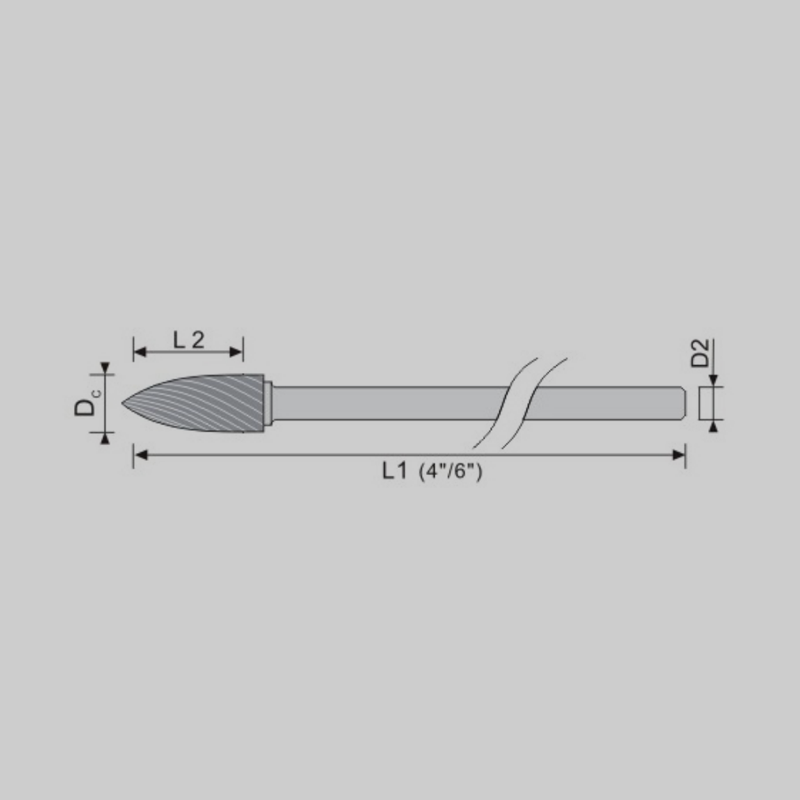

Long Shank Burr Manufacturer

Long Shank Burs, a specialized subset of Standard Rotary Burs (Fractional), represent precision machining tools engineered to provide extended reach and versatility in various industrial applications. These burs are meticulously designed to offer exceptional capabilities tailored to meet the demands of tasks requiring deeper reach or access to confined spaces.

Applications:

Long Shank Burs find wide-ranging applications across diverse industries, owing to their extended reach and precision cutting abilities. In the automotive sector, they are invaluable for tasks such as porting and polishing engine cylinders or deburring complex components. Additionally, in the aerospace industry, Long Shank Burs play a vital role in machining intricate components within aircraft engines or fuselages, where access is often restricted. Moreover, they are utilized in industries like metalworking, mold making, and woodworking, where precise machining in deep recesses or intricate details is paramount.

Characteristics and Features:

1.Extended Reach: Long Shank Burs are characterized by their elongated shanks, enabling them to reach into deep recesses or confined spaces that standard-length burs cannot access. This unique design feature empowers precision machining in areas previously out of reach, facilitating intricate operations with unparalleled accuracy and efficiency.

2. Precision Cutting: Equipped with razor-sharp cutting edges and fine tooth configurations, these Long shank burs excel in achieving precise material removal, ensuring surface finishes and dimensional accuracy.

3.High-Quality Construction: Constructed with top-tier materials, Long Shank Burs boast durability and longevity, making them resilient companions even in the demanding machining environments. This high-quality craftsmanship ensures prolonged performance and reliability, enabling these burs to endure rigorous use and excel in high-intensity machining operations without compromising precision or efficiency.

4.Versatility: In addition to their compatibility with die grinders, electric drills, and CNC machines, Long Shank Burs exhibit remarkable versatility, seamlessly integrating into a wide array of machining setups. This adaptability caters to diverse application requirements, accommodating the evolving needs of different industries and machining tasks. Whether used in aerospace, automotive, or metalworking applications, these burs remain versatile allies, ensuring performance and efficiency across varied machining environments.

Advantages:

1.Extended Reach: The elongated shanks of Long Shank Burs provide extended reach, enabling access to deep recesses or confined spaces, allowing for precision machining in areas previously inaccessible.

2.Precision Cutting: With their razor-sharp cutting edges and fine tooth configurations, these Long shank burs ensure precise material removal, resulting in surface finishes and dimensional accuracy, reducing the need for additional finishing processes.

3.Enhanced Versatility: Long Shank Burs offer versatility in machining setups, compatible with a range of rotary tools, allowing for seamless integration into existing workflows and machining environments.

4.Improved Efficiency: By extending the reach of machining operations, these burs optimize efficiency, reducing the need for tool changes and setup adjustments, thus streamlining the machining process and improving overall productivity.

To summarize, Long Shank Burs represent the pinnacle of precision machining tools, providing unmatched capabilities for a diverse array of industrial applications. Their extended reach and outstanding cutting performance redefine the boundaries of machining possibilities, enabling manufacturers to achieve unparalleled results. With a blend of versatility, precision, and specialized solutions, these burs serve as catalysts for efficiency and innovation across manufacturing processes, setting new standards for excellence in the industry.