Introduction to Cutting Speed Considerations

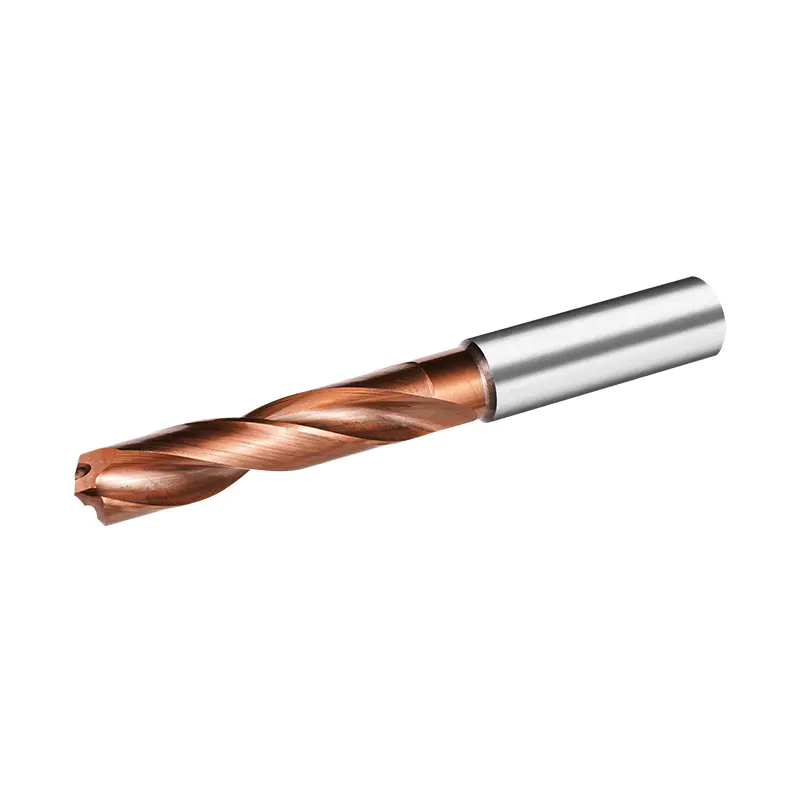

Solid Carbide Burs are essential tools in metalworking, woodworking, and precision machining due to their hardness and durability. One of the most critical factors in achieving suitable results is understanding how cutting speed interacts with the material being processed. Cutting speed directly affects efficiency, surface quality, tool wear, and overall productivity. By analyzing the behavior of these burs across different materials, operators can make informed decisions to improve performance and extend tool life.

Performance with Soft Materials

When machining soft materials such as aluminum, brass, copper, or certain plastics, cutting speed can typically be higher without compromising tool life. These materials offer less resistance to the cutting edge, allowing burs to remove material efficiently while producing smooth surfaces. High-speed operation in soft materials reduces processing time, but operators must remain cautious of material buildup within the bur’s flutes, which can affect cutting precision. Proper lubrication and chip removal are essential to maintain suitable performance during extended use on softer substrates.

Behavior on Medium-Hard Materials

Medium-hard materials, including mild steel, bronze, and certain alloys, present a more moderate challenge. Cutting speed must be carefully adjusted to balance efficiency with tool preservation. Excessive speed can generate heat, dull the cutting edges, and accelerate wear, while too slow a speed may result in inefficient material removal. The geometry of the bur, including flute design and tip shape, plays a significant role in controlling cutting forces and heat buildup. Using burs with optimized flute patterns can enhance chip evacuation, maintain cutting efficiency, and improve surface quality on medium-hard materials.

Challenges with Hard Materials

Hard materials, such as stainless steel, titanium, and hardened tool steels, significantly impact the suitable cutting speed. Due to increased resistance, burs require slower rotational speeds to avoid excessive heat generation and premature wear. High-speed operation in these materials can cause chipping or fracturing of the cutting edges, reducing tool life and potentially damaging the workpiece. Specialized coatings or advanced carbide formulations may help improve durability and allow for slightly higher cutting speeds, but caution is essential to prevent tool failure. Heat management, through intermittent cutting or external cooling, becomes particularly important when working with hard materials.

Influence of Material Composition

Material composition, in addition to hardness, influences cutting speed performance. Alloys with varying grain structures or embedded particles can alter the interaction between the bur and the workpiece. Abrasive inclusions, work-hardening tendencies, or variable density regions can reduce cutting efficiency and increase tool wear. Understanding these material-specific characteristics allows operators to adjust rotational speed, feed rate, and cooling strategies to maintain suitable performance. Choosing the correct bur geometry for the material type is equally critical to achieving consistent results.

Practical Recommendations for Operators

To improve the performance of Solid Carbide Burs, operators should select cutting speeds tailored to the specific material. Softer materials allow higher speeds but require attention to chip accumulation. Medium-hard materials demand a balance between speed and durability, with careful monitoring of heat. Hard materials require lower speeds, effective cooling, and consideration of specialized coatings or bur geometries. Regular inspection of burs, proper maintenance, and adherence to manufacturer guidelines further ensure consistent cutting efficiency and extended tool life.

Cutting speed performance of Solid Carbide Burs varies significantly across different materials. Soft materials allow fast, efficient cutting, medium-hard materials require balanced speed, and hard materials demand slower operation with heat management strategies. By understanding the relationship between cutting speed and material type, operators can optimize efficiency, improve surface finish, and extend the lifespan of their tools. Proper selection, operational adjustment, and maintenance practices are essential to achieve reliable and consistent results in any machining application.