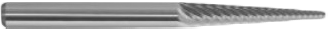

Thermal Characteristics of Solid Carbide Burs

Solid Carbide Burs are widely recognized for their good hardness and cutting efficiency, but like any cutting tool, they inevitably generate heat during machining. The amount of heat produced depends on various factors such as cutting speed, feed rate, material hardness, and cooling methods. Understanding how and why heat is generated when using Solid Carbide Burs is essential for optimizing performance and tool life.

Factors Influencing Heat Generation

The primary source of heat during the use of Solid Carbide Burs is friction between the rotating tool and the workpiece material. Higher cutting speeds and aggressive feed rates can increase this friction, causing elevated temperatures. Additionally, harder or tougher materials typically require more energy to cut, which also contributes to heat buildup. Without proper management, excessive heat can affect both the tool and the workpiece quality.

Material Properties and Heat Dissipation

Compared to conventional steel burs, Solid Carbide Burs have better heat resistance and thermal conductivity. This means they can withstand higher temperatures without losing hardness or structural integrity. However, their relatively low thermal conductivity compared to metals like aluminum means heat tends to concentrate near the cutting edge. Therefore, efficient heat dissipation relies heavily on external factors such as cooling and lubrication.

Impact of Heat on Tool Performance

Excessive heat during machining can cause premature wear, reduce the sharpness of Solid Carbide Burs, and even cause micro-cracks or fractures in extreme cases. High temperatures may also cause thermal expansion, resulting in dimensional inaccuracies in precision work. Furthermore, heat buildup can alter the metallurgical properties of the workpiece, potentially causing surface hardening or discoloration, which is undesirable in many applications.

Cooling and Lubrication Techniques

To reduce heat generation and maintain suitable tool performance, effective cooling and lubrication are critical. Using cutting fluids or coolants reduces friction and carries heat away from the cutting zone. Many machining setups incorporate flood coolant systems or misting sprays specifically designed for Solid Carbide Burs. Proper coolant selection and application not only protect the tool but also improve surface finish and machining accuracy.

Optimizing Cutting Parameters

Adjusting cutting parameters such as speed, feed rate, and depth of cut can also help control heat buildup. Lowering the cutting speed reduces frictional heat, while optimizing the feed rate prevents excessive tool loading. In some cases, multiple shallow passes are preferred over a single deep cut to reduce thermal stress. Operators should follow manufacturer guidelines for recommended parameters tailored to Solid Carbide Burs and the specific materials being machined.

Signs of Overheating and Preventive Measures

Operators can monitor signs of overheating, including discoloration of the bur, unusual tool wear patterns, or changes in machining noise and vibration. Implementing regular inspections and maintenance schedules helps detect potential issues early. Additionally, ensuring the machine setup is stable and the tool is properly mounted reduces unnecessary heat caused by tool chatter or misalignment.

Conclusion: Heat Management Is Key to Improving Solid Carbide Bur Burs' Efficiency

While Solid Carbide Burs do generate heat during machining, their advanced material properties allow them to handle higher temperatures better than many alternatives. However, managing heat through proper cutting parameters, effective cooling, and regular monitoring is essential to prevent tool damage and ensure consistent performance. By understanding and controlling heat generation, operators can fully leverage the benefits of Solid Carbide Burs in precision and heavy-duty applications alike.