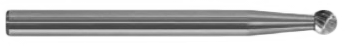

Precision machining demands tools that offer good accuracy, durability, and versatility. Among these, Solid Carbide Burs have gained prominence for their good performance in producing detailed and fine finishes. This article explores how it performs in precision machining, highlighting its key advantages and considerations for suitable use.

Good Accuracy and Cutting Precision

Solid Carbide Burs are engineered with extremely hard and wear-resistant materials, allowing them to maintain sharp edges for prolonged periods. This sharpness directly contributes to good cutting precision, enabling operators to achieve intricate details and tight tolerances required in high-precision work. Whether deburring micro-components or engraving delicate surfaces, these burs excel in delivering clean, accurate cuts with variations.

Durability Suited for Repetitive Precision Tasks

In precision machining, tool consistency is critical. Solid Carbide Burs exhibit good wear resistance compared to conventional tools, ensuring stable performance throughout extended production cycles. This durability means less frequent tool changes, reducing downtime and maintaining process reliability. Their toughness also reduces the risk of chipping or fracturing when working on delicate or complex geometries, which is vital for preserving component integrity.

Effective on Hard and Exotic Materials

Precision machining often involves working with hard or exotic materials such as titanium, stainless steel, and advanced alloys. Solid Carbide Burs are well-suited for these applications due to their ability to cut efficiently through tough substrates without losing edge sharpness. Their rigid structure reduces vibrations that could otherwise degrade surface finish quality or dimensional accuracy, making them indispensable in aerospace, medical, and automotive industries.

Versatility Across Various Precision Operations

Available in a wide array of shapes, sizes, and cutting patterns, Solid Carbide Burs offer versatility to suit diverse machining tasks. From shaping and contouring to grinding and fine polishing, these burs adapt well to various materials and finishes. This flexibility makes them a go-to tool in workshops requiring precision in multiple manufacturing stages, ensuring suitable results across different component types.

Enhanced Surface Finish Quality

One of its standout features in precision machining is its ability to produce good surface finishes. The sharp cutting edges and stable operation reduce burr formation and surface irregularities, which often require additional finishing steps. By delivering smoother surfaces directly from the cutting process, these burs help streamline workflows, saving time and costs associated with post-processing.

Considerations for Performance

While Solid Carbide Burs are highly effective, their performance depends on proper application. Operators must adhere to recommended cutting speeds, feed rates, and cooling methods to prevent overheating and premature wear. Using appropriate coolant systems helps dissipate heat and prolong tool life. Regular inspection and maintenance are also essential to ensure continued precision and efficiency.

Impact on Productivity and Cost Efficiency

The combination of accuracy, durability, and versatility means that Solid Carbide Burs can significantly enhance productivity in precision machining environments. Their long tool life reduces material waste and machine downtime, while high-quality finishes decrease rework. Although they may have a higher initial cost than conventional burs, the overall return on investment is favorable due to improved machining efficiency and product quality.

Conclusion: Solid Carbide Burs as a Key Asset in Precision Machining

Solid Carbide Burs demonstrate performance in high-precision machining applications through their accuracy, durability, and adaptability. Their ability to handle challenging materials and deliver superior finishes makes them essential tools in industries demanding exacting standards. When properly used and maintained, it contributes to enhanced manufacturing quality, efficiency, and cost-effectiveness in complex machining processes.