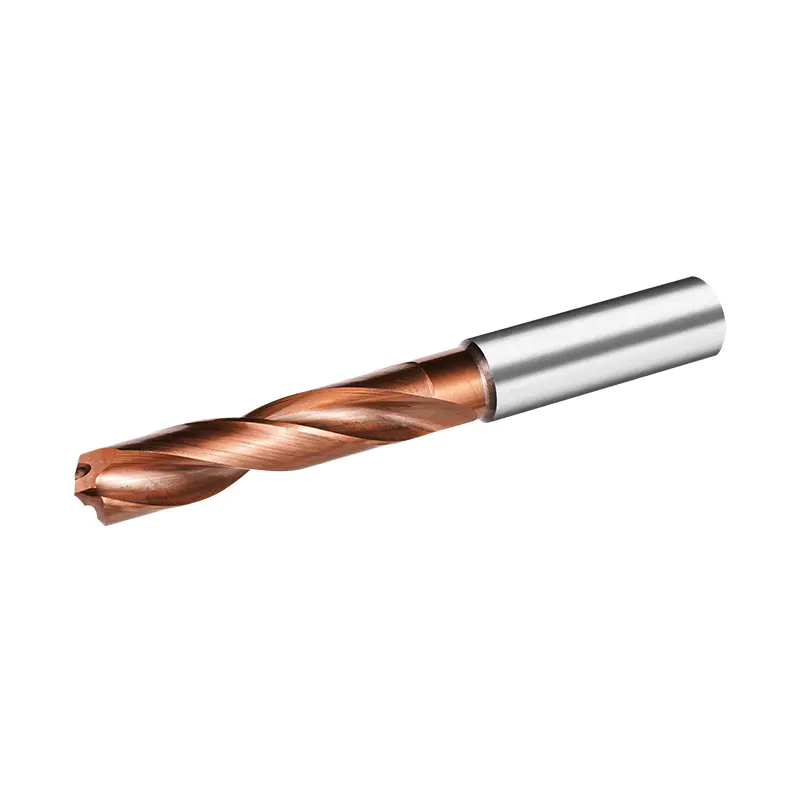

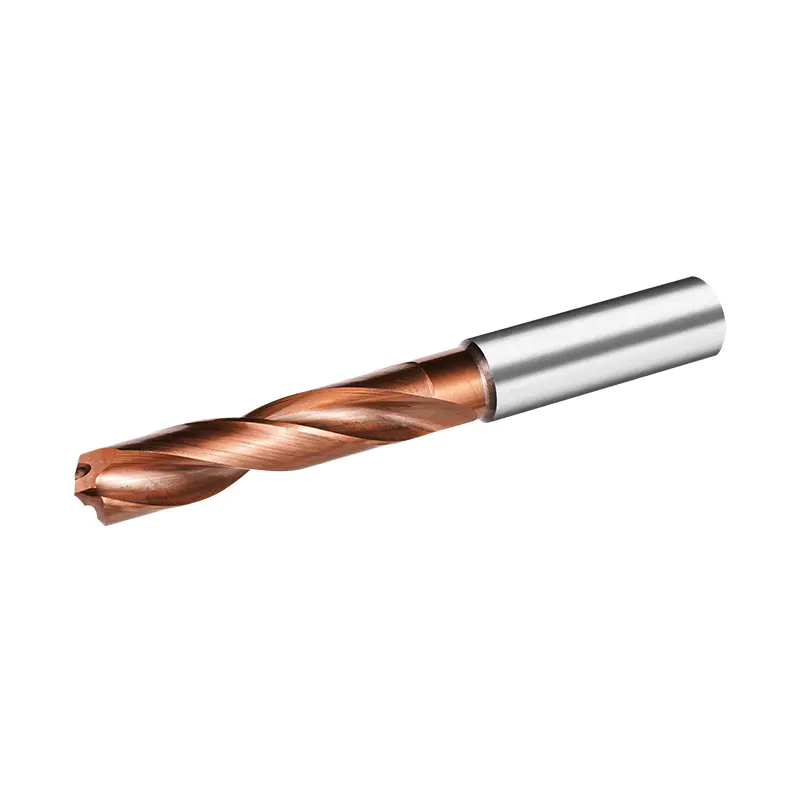

Versatility Across Machine Platforms

Solid Carbide Burs are widely utilized in industrial, dental, and precision applications due to their durability and cutting efficiency. Their performance, however, can vary significantly depending on the type of machine they are used with. Understanding how these burs adapt to handheld electric tools versus CNC machines is critical for optimizing cutting precision, tool life, and operational safety.

Compatibility with Handheld Electric Tools

- Ease of Use: Handheld electric tools, such as rotary drills and die grinders, allow operators to use Solid Carbide Burs for detailed and localized work. The compact design of these burs ensures compatibility with standard collets and chucks.

- Speed and Control: Operators must carefully control rotational speed and applied pressure. High-speed handheld operation can generate heat, potentially reducing bur lifespan or causing minor deformation if improperly managed.

- Ergonomic Considerations: Handheld applications require burs with balanced shank design to reduce vibration and operator fatigue, ensuring consistent precision during manual work.

- Material Limitations: While suitable for metals, plastics, and composites, hand tools may struggle with thicker or harder workpieces, where maintaining consistent feed pressure is more challenging.

Compatibility with CNC Machines

- Precision and Automation: CNC machines provide highly controlled rotational speed, feed rates, and tool paths, making them ideal for Solid Carbide Burs. The precise motion reduces vibration and ensures consistent engagement with the workpiece.

- High-Speed Performance: CNC platforms allow burs to operate at speeds for various materials, enhancing cutting efficiency and prolonging tool life. Automated cooling and lubrication systems further protect the bur from thermal stress.

- Repeatability: CNC machines enable repeated operations with deviation, critical for applications requiring tight tolerances. Solid Carbide Burs maintain their cutting geometry over long production runs, benefiting from consistent machine control.

- Complex Geometry Machining: CNC machines allow the burs to perform intricate cuts and 3D contours that are difficult or impossible with handheld tools. This capability improves the burs’ versatility in industrial and precision applications.

Operational Considerations Across Machine Types

- Shank and Collet Compatibility: Selecting burs with appropriate shank diameters ensures proper fit in both handheld tools and CNC collets, preventing wobble and vibration.

- Heat Management: Regardless of machine type, heat dissipation is crucial. CNC machines often incorporate coolant systems, whereas handheld tools require careful speed control and intermittent operation to prevent overheating.

- Vibration and Stability: Solid Carbide Burs rely on stable rotation for precision. CNC machines inherently reduce vibration, while handheld operation demands operator skill and ergonomic burdens to maintain stability.

- Material-Specific Adjustments: Harder materials like steel or titanium benefit from CNC machining due to controlled feed and speed, whereas softer materials like aluminum or plastics are manageable with both handheld and automated tools.

Safety and Tool Life Considerations

- Operator Safety: Handheld applications pose a higher risk of slippage or improper handling, so burs must be properly secured, and operators trained in speed and feed control.

- Prolonged Use: CNC machining reduces operator error, extending bur life by maintaining consistent cutting parameters, reducing wear, and reducing the risk of thermal damage.

- Maintenance: Regular inspection for wear, chipping, or shank deformation is essential in both machine types to ensure continued precision and safety.

Optimizing Solid Carbide Burs for Machine Adaptation

Solid Carbide Burs demonstrate remarkable adaptability to both handheld electric tools and CNC machines, but their performance depends on proper machine compatibility and operational control. Handheld tools offer flexibility for localized or intricate work but require careful speed, pressure, and ergonomic considerations. CNC machines provide precision, repeatability, and suitable speed control, allowing the burs to perform high-efficiency, complex, and long-duration operations. By selecting appropriate burs, considering shank compatibility, and managing heat and vibration, users can improve the efficiency, durability, and precision of Solid Carbide Burs across diverse machining platforms.